Injection moulding systems for preforms and caps

Most bottlers and beverage manufacturers purchase their preforms and caps. Why is that?

In-house production offers you all sorts of benefits, mainly:

- Greater independence from external influences

- Individual design flexibility in line with your requirements

- Total control over production processes and their results

- Security and flexibility for the future

It is easy to become your own supplier

You can receive just the right injection moulding systems from the Krones subsidiary IPS Plastics – including know-how on how you can ideally operate them and much more. After all, from the preform and cap design right through to the overhaul or replacement of older systems: you can always count on the individual support of our injection moulding professionals.

The spectrum of IPS Plastics solutions and services comprises, among other things:

- Individual preform and cap design

- Development of a tailor-made production concept

- TCO and sustainability analyses

- Planning, configuration and integration of product technology

- System installation and commissioning

- Comprehensive training measures for your production team

- Maintenance and support for the entire system life cycle

- Upgrades and overhauls for a long service life

- Expansion or replacement of existing systems

Injection moulding machine “IMM”

- E-clamp with recuperation

- Smart operation

- Sutiable for 100 percent rPET

Dryer concept/platform

- Silo on top and booster options

- Customized platforms

- Suitable for 100 percent rPET

Chiller system and T/P

- Air-, dry-, or water condensed

- Tank/Pump unit on a skid

- Piping and insulation

Dehumidifier

- Dry air with dew point control

- Additional option for cool air

Mould and robot

- Up to 144 cavity

- EOT with inner cooling

- Optimized hotrunner for rPET

Conveyor

- Box loading

- Inline and offline inspection systems

- Various preform handling systems

Material handling

- Silos and big-bag unloading stations

- Distribution and conveying

- Dedusting and mixing

Additive device

- Masterbatch or liquid

- Volumetric and gravimetric solution

Inline inspection system

- 100 percent inspection: inside and outside

- Pinhole and cavity reading

- Up to 3.600 caps per minute

Cap conveyor and sorting system

- Cap cooler

- Bad part chute

- CAP orientation with bunker

Injection moulding machine “IMM”

- E-clamp with recuperation

- Smart operation

- Integrated downstream

Closure mould

- Up to 128 cavity

- Integrated hotrunner (in IMM)

- Optimized gate area

Dehumidifier

- Dry air with dew point control

- Additional option for cool air

Material handling/Additive

- Loading station with bins

- Master batches and additive

- Volumetric and gravimetric options

Chiller system

- Air-, dry-, or water condensed

- Piping and insulation

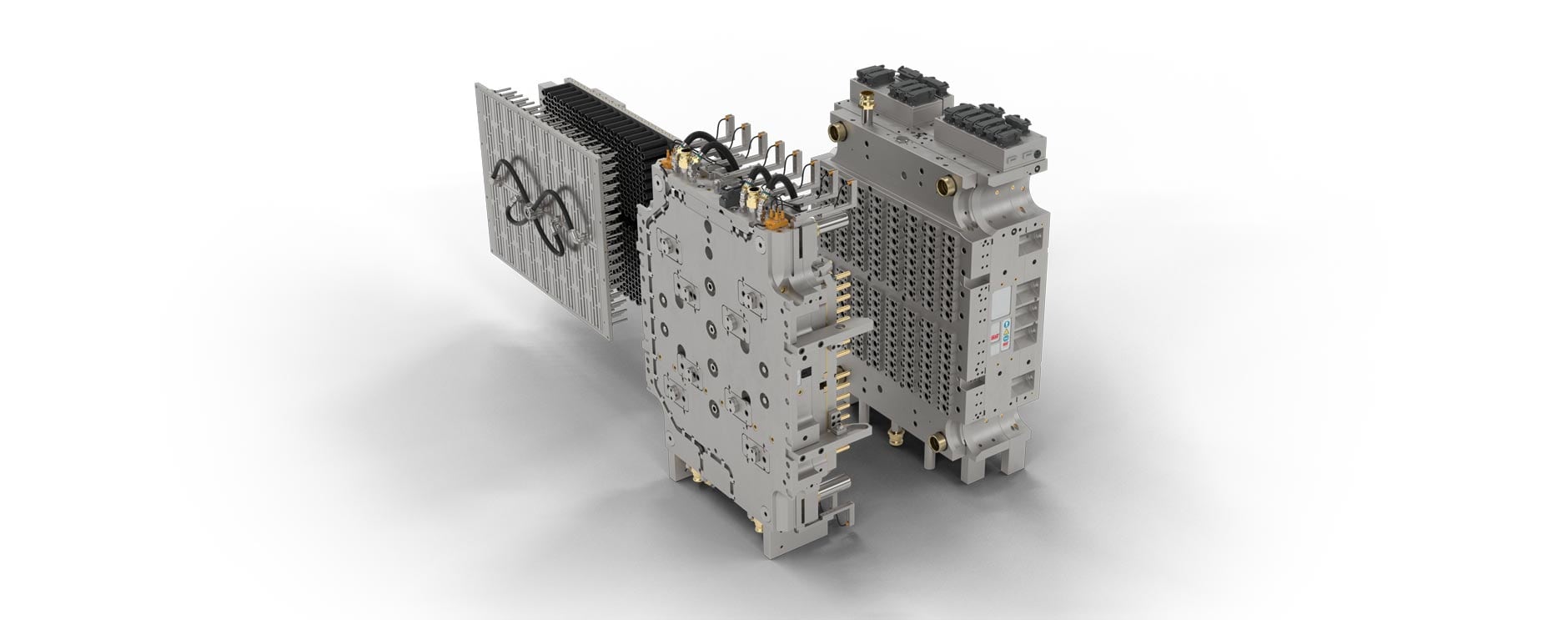

Injection moulding tools for each system type

They are at the heart of every preform production process: injection moulding tools have a considerable impact on the process quality, output and sustainability of your line. To ensure that you can get the maximum benefit despite all these factors, the tools are designed and manufactured to suit your individual needs. Krones subsidiary, MHT Mold & Hotrunner Technology AG, has specialised in precisely this. As an independent supplier, it equips all the familiar machine systems with custom-fit tools.

With their up to 192 cavities, MHT tools are dedicated to working at high speed. They also provide each individual preform with an entire list of benefits, including:

- No crystallinity or scratches

- High surface quality

- Low acetaldehyde level

- Seamless mould partitions

- Minimum eccentricity

- High stability

- Consistent weight

PET tools for perfect preform quality

coolMAX

- Up to four stages

- Staggered version available

- Gripper pins, standard or spring loaded

- Air baffle (for thread cooling)

- For all cavitations

- Bladder function available

Take-OUT Plate

- Up to four stages EAOT

- Exchangeable cooling sleeves

- Cooling sleeves with MHTxCOOL

Cold half

- Up to 144 cavities

- Up to 750 g preforms, for bottles up to 30 l

- Preform molds for PE, PP, PLA

optiSTACK

- Innovative two-piece core design

- Increased standardized parts (warehouse stock)

- Quick and easy weight-change

- Quick and easy splitline refurbishment

- Advanced two-piece cooling tube design

- Proven MHT two-piece HP-Stack technology

optiRUN

- For molds from 48 to 144 cavities

- Modular hotrunner packages

- Small-volume individually regulated heating zones

- Perfectly balanced heat distribution

- Cooled adapter plates

- Vulcan II components by default